15M 20M 25M 30M 35M Automatic Lift Solar High Mast Light Pole

Requirements for the construction site environment

The installation site of the high mast light pole should be flat and spacious, and the construction site should have reliable safety protection measures. The installation site should be effectively isolated within a radius of 1.5 poles, and non-construction personnel are prohibited from entering. The construction personnel must take various safety protection measures to ensure The life safety of construction workers and the safe use of construction machinery and tools.

Construction steps

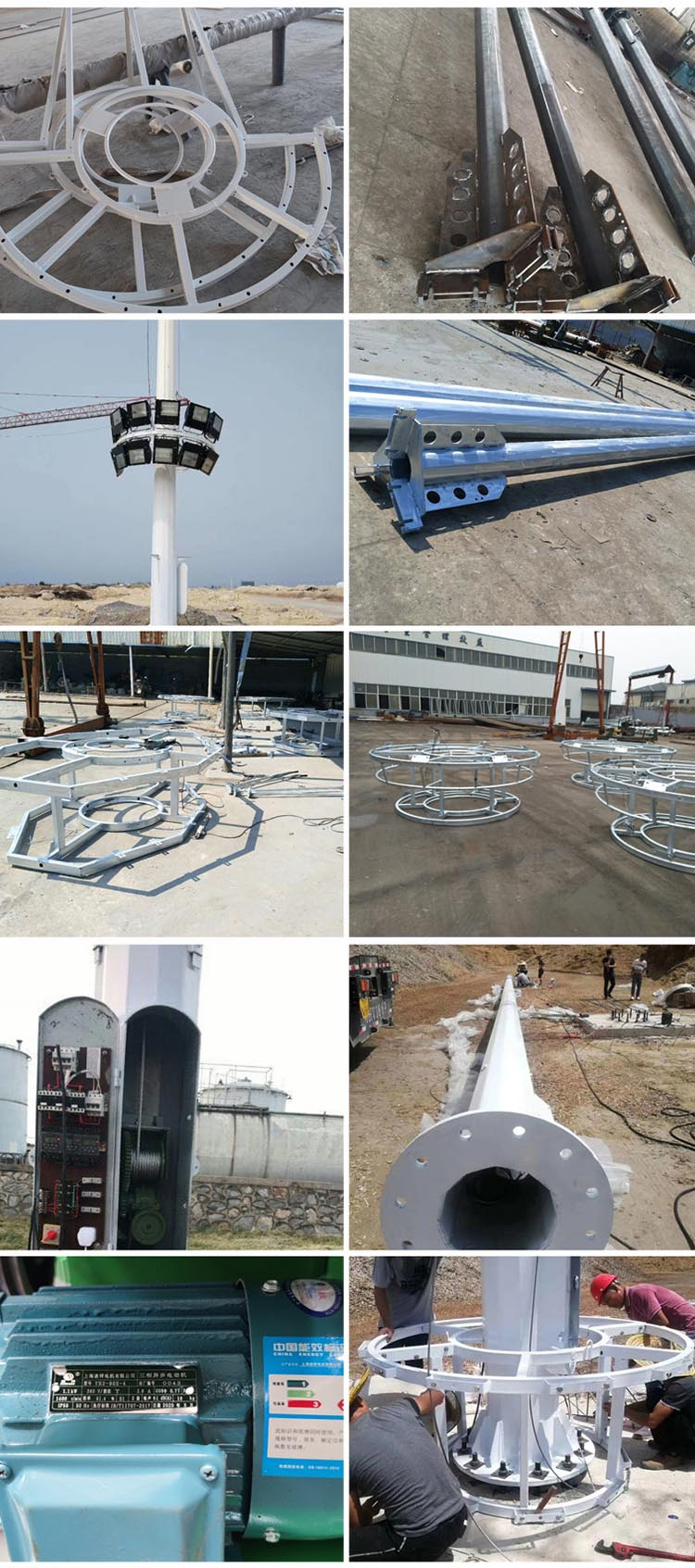

1. When using the high mast light pole from the transport vehicle, put the flange of the high pole lamp close to the foundation, and then arrange the sections in order from large to small (avoid unnecessary handling during the joint);

2. Fix the light pole of the bottom section, thread the main wire rope, lift the second section of light pole with a crane (or a tripod chain hoist) and insert it into the bottom section, and tighten it with the chain hoist to make the internode seams tight , straight edges and corners. Be sure to put it into the hook ring correctly (distinguish the front and back) before inserting the best section, and the integral lamp panel must be pre-inserted before inserting the last section of light pole;

3. Assembling spare parts:

a. Transmission system: mainly includes hoist, steel wire rope, skateboard wheel bracket, pulley and safety device; the safety device is mainly the fixing of three travel switches and the connection of control lines. The position of the travel switch must meet the requirements. It is to ensure that the travel switch It is an important guarantee for timely and accurate actions;

b. The suspension device is mainly the correct installation of the three hooks and the hook ring. When installing the hook, there should be an appropriate gap between the light pole and the light pole to ensure that it can be easily detached; the hook ring must be connected before the last light pole. put on.

c. Protection system, mainly the installation of rain cover and lightning rod.

Hoisting

After confirming that the socket is firm and all parts are installed as required, the hoisting is carried out. Safety must be achieved during hoisting, the site should be closed, and the staff should be well protected; the performance of the crane should be tested before hoisting to ensure safety and reliability; the crane driver and personnel should have corresponding qualifications; be sure to insure the light pole to be hoisted, Prevent the socket head from falling off due to force when it is hoisted.

Lamp panel and light source electrical assembly

After the light pole is erected, install the circuit board and connect the power supply, motor wire and travel switch wire (refer to the circuit diagram), and then assemble the lamp panel (split type) in the next step. After the lamp panel is completed, assemble the light source electrical appliances according to the design requirements.

Debugging

The main items of debugging: the debugging of light poles, the light poles must have precise verticality, and the general deviation should not exceed one thousandth; the debugging of the lifting system should achieve smooth lifting and unhooking; The luminaire can work normally and effectively.

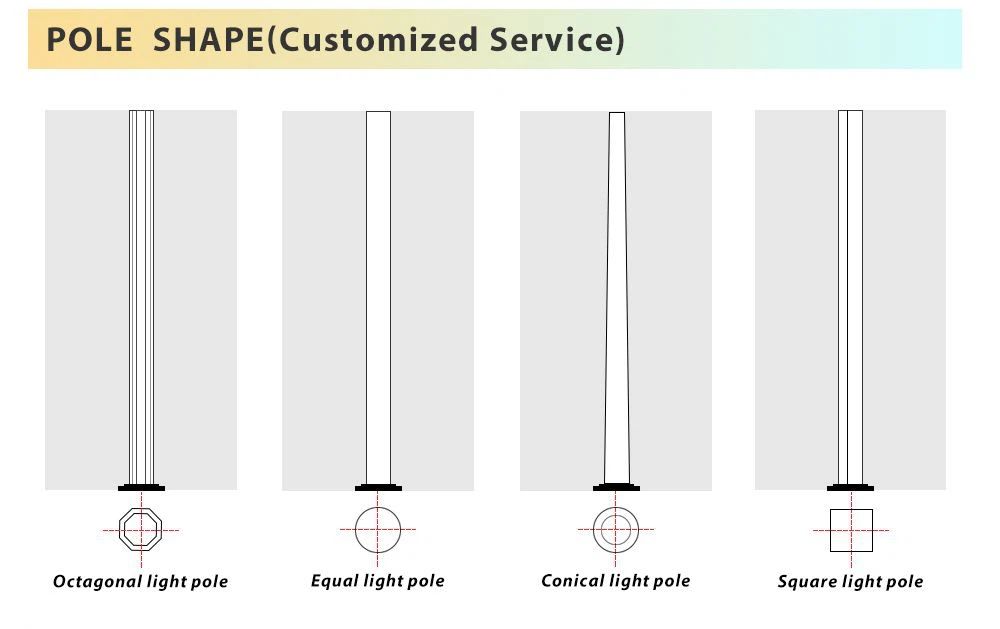

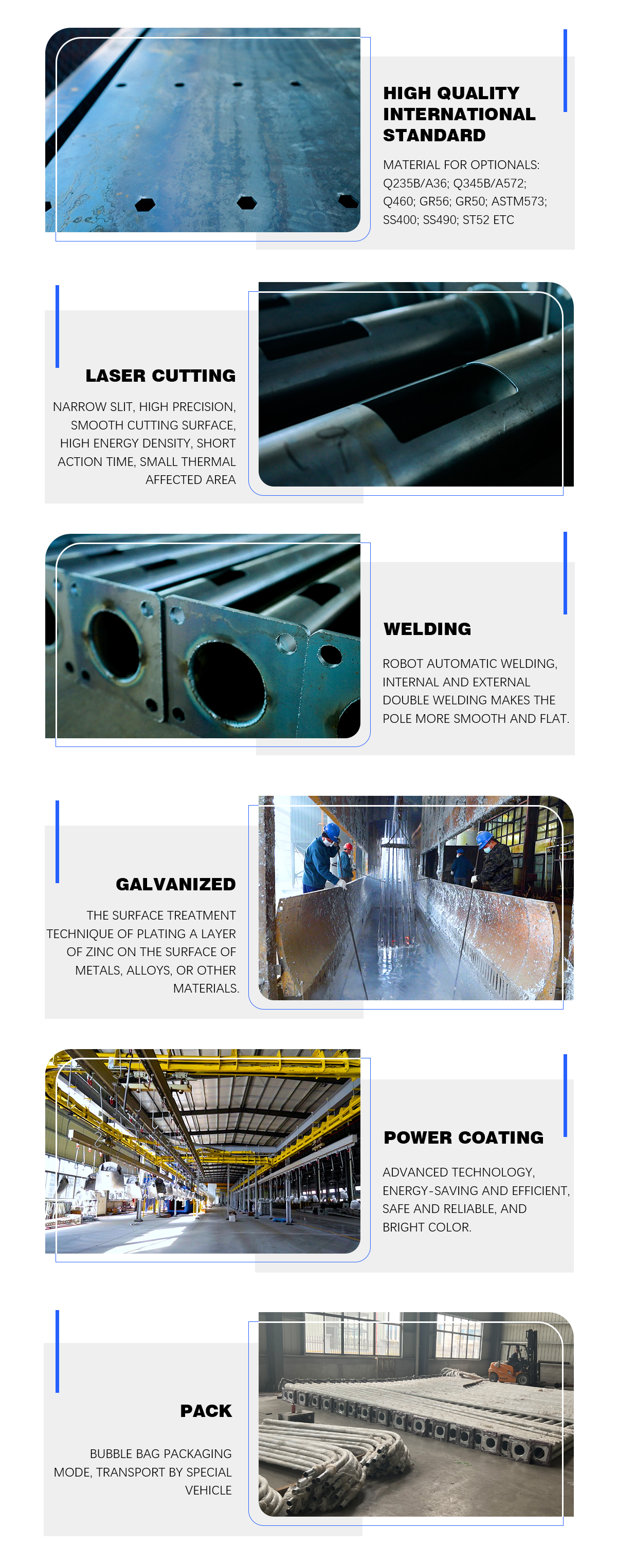

High mast light pole refers to a new type of lighting device composed of a steel column-shaped light pole with a height of 15 meters and a high-power combined light frame. It consists of lamps, internal lamps, poles and basic parts. It can complete the automatic lifting system through the motor of the electric door , easy maintenance. Lamp styles can be determined according to user requirements, surrounding environment, and lighting needs. Internal lamps are mostly composed of floodlights and floodlights. The light source is Led or high-pressure sodium lamps, with a lighting radius of 80 meters. The pole body is generally a single-body structure of a polygonal lamp pole, which is rolled with steel plates. Light poles are hot-dip galvanized and powder-coated, with a lifespan of more than 20 years, more economical with aluminum and stainless steel.