1. Light source

The light source is an important part of all lighting products. According to different illumination requirements, different brands and types of light sources can be selected. Commonly used light sources include: incandescent lamps, energy-saving lamps, fluorescent lamps, sodium lamps, metal halide lamps, ceramic metal halide lamps, And new LED light source.

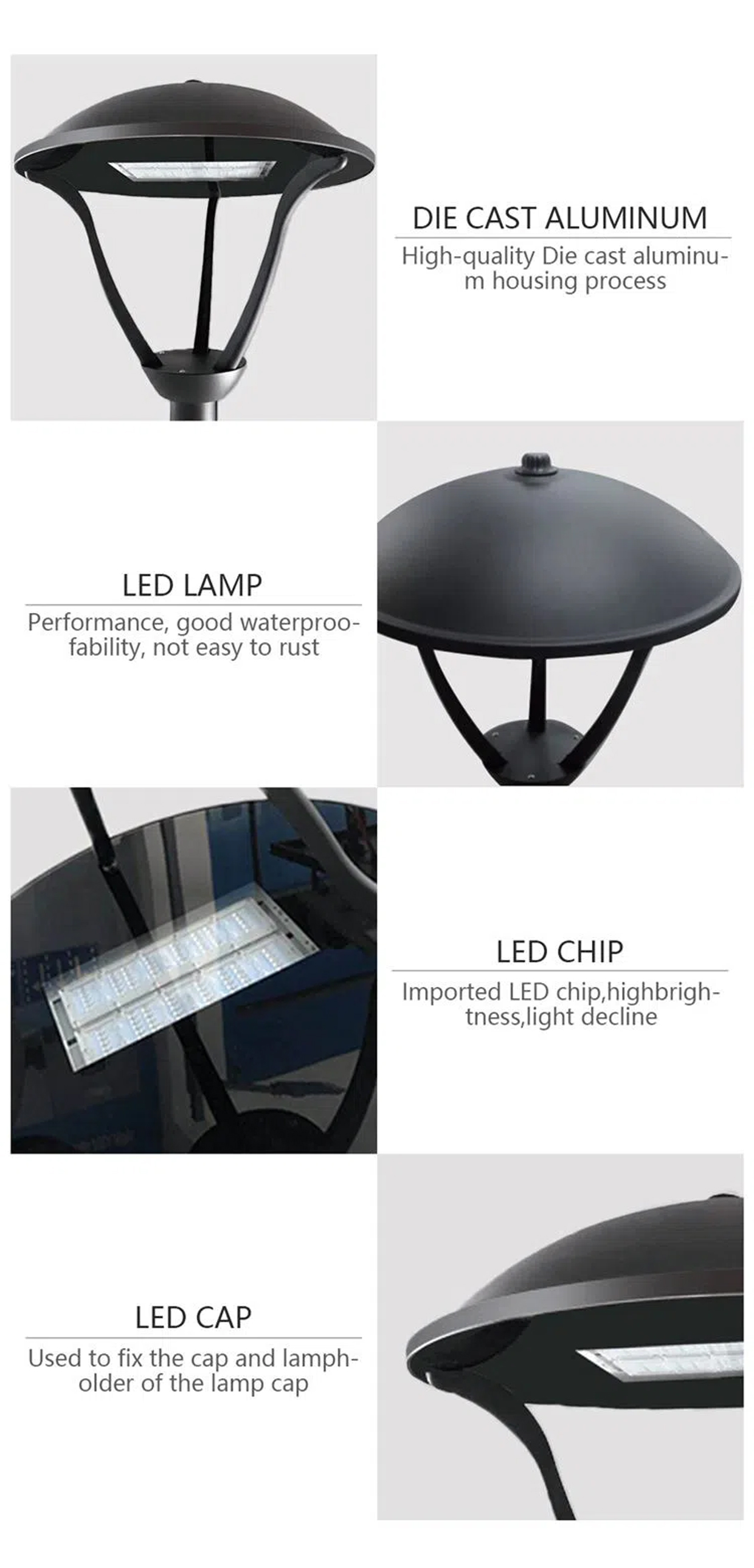

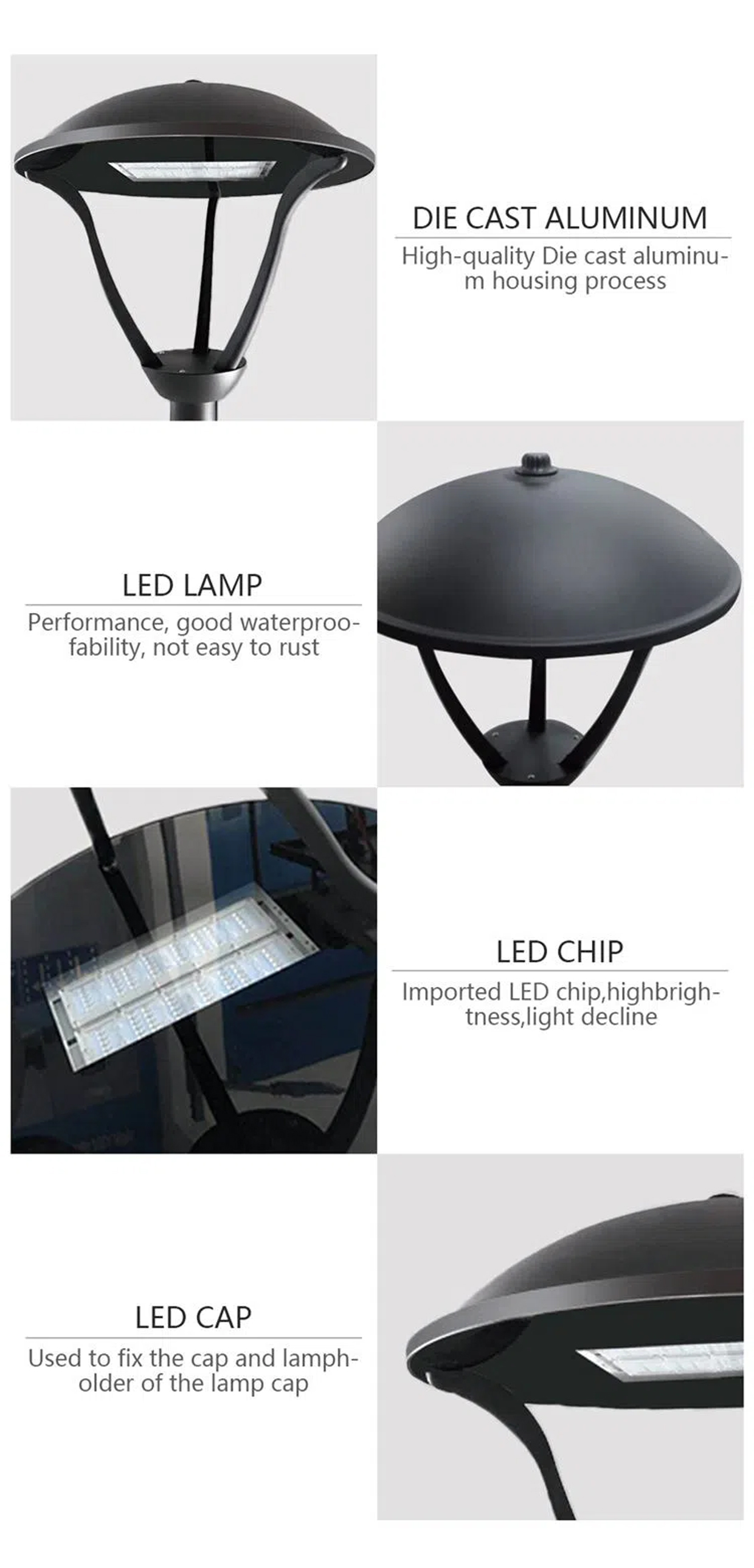

2. Lamps

The transparent cover with a light transmittance of more than 90%, a high IP rating to prevent the penetration of mosquitoes and rainwater, and a reasonable light distribution lampshade and internal structure to prevent glare from affecting the safety of pedestrians and vehicles. Cutting wires, welding lamp beads, making lamp boards, measuring lamp boards, coating thermally conductive silicone grease, fixing lamp boards, welding wires, fixing reflectors, installing glass covers, installing plugs, connecting power lines, testing, aging, inspection, labeling , Packing, storage.

3. Lamp pole

The main materials of IP65 garden light pole are: equal diameter steel pipe, heterosexual steel pipe, equal diameter aluminum pipe, cast aluminum light pole, aluminum alloy light pole. Commonly used diameters are Φ60, Φ76, Φ89, Φ100, Φ114, Φ140, and Φ165. According to the height and the place used, the thickness of the selected material is divided into: wall thickness 2.5, wall thickness 3.0, and wall thickness 3.5.

4. Flange

Flange is an important component of IP65 light pole and ground installation. IP65 garden light installation method: Before installing the garden light, it is necessary to use M16 or M20 (commonly used specifications) screws to weld the foundation cage according to the standard flange size provided by the manufacturer. The cage is placed in it, and after the level is corrected, it is poured with cement concrete to fix the foundation cage. After 3-7 days, the cement concrete is fully solidified, and the IP65 garden light can be installed.