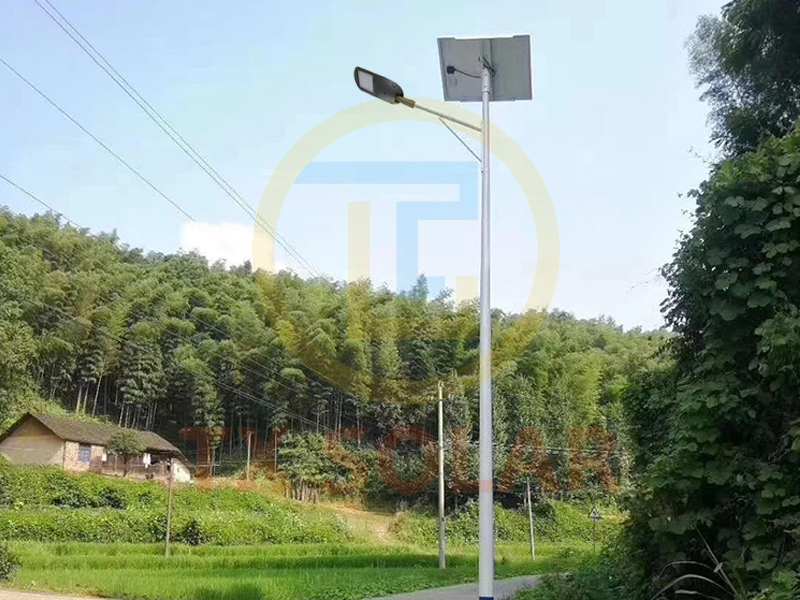

The adoption of renewable energy has gained momentum in recent years, especially in rural areas where electricity supplies are limited. One of the most effective solutions to improve safety and visibility in your village is to install solar street lights. These lights not only provide illumination but also promote sustainability by harnessing solar energy. Understanding the production process of rural solar street lights is critical to ensuring their efficiency, durability and effectiveness in rural environments.

1. Conceptualization and Design

The production process of village solar street lights starts with conceptualization and design. Engineers and designers collaborate to create products that meet the specific needs of rural communities. Factors such as average daylight hours, local weather conditions and the intended use of the lights are taken into account. The design phase also included selecting durable and weather-resistant materials to ensure the lights can withstand harsh environmental conditions.

2. Prepare Materials

Rural solar street lights usually consist of several key components:

- Solar Panels: They are the heart of the system, converting sunlight into electricity. High-efficiency photovoltaic cells are preferred to maximize energy capture.

- Battery: Rechargeable batteries store the energy produced by solar panels. Typically lithium-ion or lead-acid batteries are used, depending on budget and energy needs.

- LED Lamps: Light emitting diodes (LEDs) are favored for their energy efficiency and long life. They provide bright illumination while consuming minimal power.

- Pole and Mounting Hardware: Structural components must be strong enough to support the solar panels and lights, and are usually made of galvanized steel to prevent rust.

- Control System: This includes sensors and timers to regulate when lights turn on and off, optimizing energy use.

3. Manufacturing Components

Each component is produced individually:

- Solar Panels: The production of solar panels involves multiple steps, including making silicon wafers, doping them to form pn junctions, and assembling them into panels. At this stage, quality control is critical to ensure the panels meet efficiency standards.

- Battery: Battery manufacturing involves assembling the battery, connecting it and encasing it in a protective case. Safety testing is performed to ensure they can handle a variety of environmental conditions.

- LED: The production of LEDs involves the growth of semiconductor materials, followed by the manufacturing of LED chips. The chips were then mounted onto a circuit board and tested for brightness and efficiency.

- Pole and Mounting Hardware: Rods are manufactured through a process such as extrusion or welding, then surface treated for enhanced durability.

4. Assembly

Once all components are manufactured, the assembly process begins. This stage involves integrating the solar panels, batteries, LEDs and control system into a single unit. Skilled technicians ensure that all connections are tight and the system is properly calibrated. This step is critical as any errors in assembly can lead to malfunction or reduced efficiency.

5. Quality Control

Quality control is an integral part of the production process. Each assembled solar street light undergoes rigorous testing to ensure it meets performance standards. Testing may include:

- Electrical Test: Verify that the solar panels produce the expected voltage and that the battery holds a charge.

- Lighting Test: Evaluates the brightness and distribution of light emitted by LEDs.

- Durability Test: Expose lights to a variety of environmental conditions such as extreme temperatures, humidity, and wind to ensure they can withstand the rigors of outdoor use.

6. Packaging and Distribution

Once the solar street lights pass quality control, they are packaged for distribution. The packaging is designed to protect the light during shipping while also being environmentally friendly. The distribution process often involves working with local governments or NGOs to ensure the lights reach the villages that need them most.

7. Installation and maintenance

The final step in the production process is installation. Local teams are often trained to install solar street lights, ensuring they are positioned to receive maximum sunlight. Maintenance is also an important aspect, as regular inspections of the solar panels, batteries and LEDs can extend the life of the lights and ensure they operate optimally.

In conclusion

The production process of rural solar street lights is a multi-faceted endeavor that combines engineering, manufacturing and community engagement. By understanding every step from design and material sourcing to assembly and installation, stakeholders can ensure these lights effectively increase safety and sustainability in rural areas. As more and more villages adopt solar street lights, they not only illuminate the streets but also pave the way for a greener, more sustainable future.

Post time: Oct-31-2024