Do you know what kind of standards should LED street light poles meet? Street light manufacturer TIANXIANG will take you to find out.

1. The flange plate is formed by plasma cutting, with a smooth periphery, no burrs, beautiful appearance, and accurate hole positions.

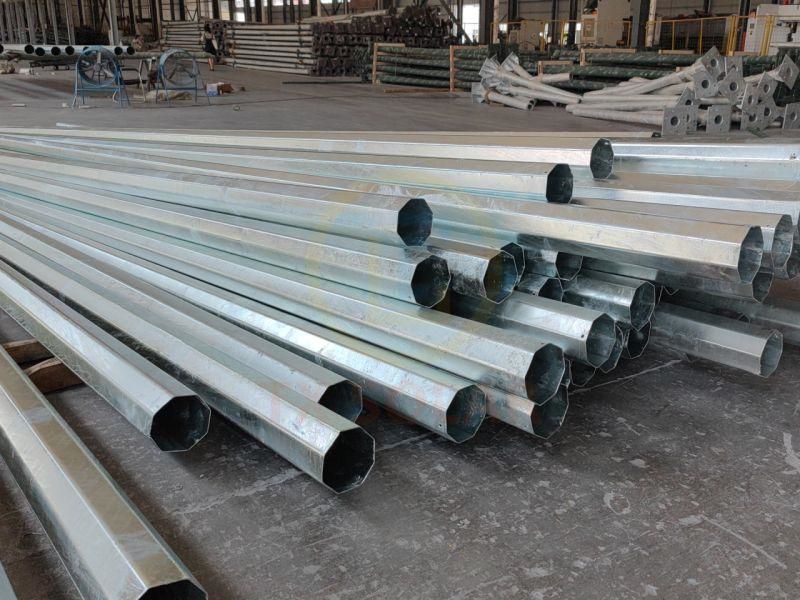

2. The inside and outside of the LED street light pole should be treated with hot-dip galvanized inner and outer surface anti-corrosion and other processes. The galvanized layer should not be too thick, and the surface has no color difference and roughness. The above anti-corrosion treatment process should meet the corresponding national standards. During the construction process, the anti-corrosion test report and quality inspection report of the light pole should be provided.

3. The surface of the LED street light pole needs to be sprayed with color, and the color should meet the requirements of the owner. High-grade paint should be used for plastic spraying, and the color is subject to the effect picture. The thickness of the sprayed plastic is not less than 100 microns.

4. LED street light poles should be calculated and subjected to force requirements according to the wind speed and force specified in the national standard. During the construction process, material descriptions and force calculations related to light poles should be provided. For light poles connected by steel ring welding, the contractor should clean up the welding joints before welding and make grooves according to regulations.

5. The hand hole door of the LED street light pole, the design of the hand hole door should be beautiful and generous. The doors are plasma cut. The electrical door should be integrated with the rod body, and the structural strength should be good. With a reasonable operating space, there are electrical installation accessories inside the door. The gap between the door and the pole should not exceed one millimeter, and it has good waterproof performance. It has a special fastening system and has good anti-theft performance. The electric door should have high interchangeability.

6. The installation of LED street light poles should comply with the relevant provisions of the corresponding national installation regulations and safety regulations. Before the light pole is installed, the appropriate hoisting equipment should be selected according to the height, weight, and site conditions of the light pole, and the position of the lifting point, the displacement and correction method should be reported to the supervision engineer for approval; when the light pole is installed, instruments should be equipped in two directions perpendicular to each other Check and adjust to ensure that the light pole is in the correct position and the pole is vertical.

7. When the LED street light pole is connected by bolts, the screw rod should be perpendicular to the penetration surface, there should be no gap between the screw head plane and the component, and there should be no more than 2 washers at each end. After the bolts are tightened, the length of the exposed nuts should not be less than two pitch.

8. After the LED street light pole is installed and corrected, the contractor should immediately carry out backfilling and compaction, and the backfilling and compaction should comply with relevant regulations.

9. The installation of the power discharge pipe of the LED street light pole shall comply with the drawings and relevant specifications.

10. LED street light pole verticality inspection: After the light pole is upright, use theodolite to check the verticality between the pole and the horizontal.

The above are the standards that LED street light poles need to meet. If you are interested in LED street light, welcome to contact street light manufacturer TIANXIANG to read more.

Post time: Aug-09-2023